| Frayed Knot Nautical Arts Flemished or Coxcombed Wheels |

The tradition of coxcombing your helm is an old one... Originally

developed to protect the wood from salt and sun on wooden wheels, it

was continued on the steel wheels commonly found on sailing craft and

the better class of motor vessels found today in pleasure service.

Since these wheels lack the belaying-pin-type protrusions found on

wooden wheels, it also provides a better grip for the hands when at the

helm, especially when encountering a quartering sea. Anyone who has

had to hang on for dear life to a slippery steel wheel in heavy weather can

attest to the remarkable grip such coxcombing can give. It is also a

decorative feature which can enhance the appearance of your cockpit and

hark back to the days when sail was a "working" form of transportation.

The wheel used in these pictures is a 15" "destroyer"-style wheel, not

something you'd usually find on a rag-bag, but much more common on

20-36' powercraft, on which it looks superb! It's small and easy to

transport and I can change the whipping and combing as required to

either demonstrate something new or I can buy one and leave it at a

marine emporium as a sample without breaking the bank. (Can't do it

with a 32" or a 40"! Costs too much!)

CLICK on any picture for a larger version (some are large... dial-up users

be warned!).

The cane is something I whipped up so that I could have a quick was of

demonstrating the five whippings it contains, as well as some of the

common sizes of turksheads available...

I charge $50.00 per hour for these wheels... A 40" can easily run into 18

to 20 hours of work, but smaller wheels are correspondingly faster to do

and so the final charge would be far less. The number and complexity of

turksheads will also affect the final cost.

You can EMAIL me for further details or to make an appointment for a

work date, or call me at 215-843-7207 to do this or ask questions. I travel

to do this (East Coast US mid-Atlantic area, from Manasquan to Cape

Henlopen) but I will travel further if there are several commissions in the

same area or..... (more information here)

developed to protect the wood from salt and sun on wooden wheels, it

was continued on the steel wheels commonly found on sailing craft and

the better class of motor vessels found today in pleasure service.

Since these wheels lack the belaying-pin-type protrusions found on

wooden wheels, it also provides a better grip for the hands when at the

helm, especially when encountering a quartering sea. Anyone who has

had to hang on for dear life to a slippery steel wheel in heavy weather can

attest to the remarkable grip such coxcombing can give. It is also a

decorative feature which can enhance the appearance of your cockpit and

hark back to the days when sail was a "working" form of transportation.

The wheel used in these pictures is a 15" "destroyer"-style wheel, not

something you'd usually find on a rag-bag, but much more common on

20-36' powercraft, on which it looks superb! It's small and easy to

transport and I can change the whipping and combing as required to

either demonstrate something new or I can buy one and leave it at a

marine emporium as a sample without breaking the bank. (Can't do it

with a 32" or a 40"! Costs too much!)

CLICK on any picture for a larger version (some are large... dial-up users

be warned!).

The cane is something I whipped up so that I could have a quick was of

demonstrating the five whippings it contains, as well as some of the

common sizes of turksheads available...

I charge $50.00 per hour for these wheels... A 40" can easily run into 18

to 20 hours of work, but smaller wheels are correspondingly faster to do

and so the final charge would be far less. The number and complexity of

turksheads will also affect the final cost.

You can EMAIL me for further details or to make an appointment for a

work date, or call me at 215-843-7207 to do this or ask questions. I travel

to do this (East Coast US mid-Atlantic area, from Manasquan to Cape

Henlopen) but I will travel further if there are several commissions in the

same area or..... (more information here)

| Wheel flemished with "running" or "French" coxcombing but with no finial turksheads installed |

| Four-strand turk covering both sides of the gap where the stanchion meets the rim. Not my favourite as the knot always comes out looking "crowded". |

| Another finishing method: Three-bight turksheads ending off the rim coxcombing. Note that they are mirror-images of each other... No small accomplishment! |

| Some of the variations available on a wheel. Click on the picture for some closeups. |

St. Mary's hitching on a wheel

stanchion... Compare to wheel

pictures to right...

Personally, I'm getting to where I

like a bare steel stanchion.. It

detracts less from the work on the

wheel's rim.

stanchion... Compare to wheel

pictures to right...

Personally, I'm getting to where I

like a bare steel stanchion.. It

detracts less from the work on the

wheel's rim.

"Reversing" or Diamond Moku hitching from the side: The

Moku gets hitched down to the side point then reverses to form

a series of diamond shapes. EXCELLENT grip qualities!

Moku gets hitched down to the side point then reverses to form

a series of diamond shapes. EXCELLENT grip qualities!

Six-bight three pass turkshead which will go

between each segment of rim and also "close

off" the top of the stanchion... This took me a

WEEK to figure out how to do and it was well

worth the time spent.. Makes a nice transition

feature! The way a wheel should look, IMO.

between each segment of rim and also "close

off" the top of the stanchion... This took me a

WEEK to figure out how to do and it was well

worth the time spent.. Makes a nice transition

feature! The way a wheel should look, IMO.

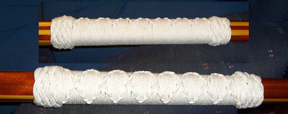

Two versions of three-strand

coxcombing: #18 cotton cord to LEFT

and #15 Nylon to RIGHT.

The Nylon makes a much smaller

braid and also "fills in" around the

wheel quite well. The cotton is larger

and coarser. Preferred for grip or

"handiness", the cotton also takes

shellac very well.

The Nylon will resist weather better but

both MUST be lacquered or varnished

once received.

Your particular location will determine

final applications and type of

lacquer/varinsh to be used.

coxcombing: #18 cotton cord to LEFT

and #15 Nylon to RIGHT.

The Nylon makes a much smaller

braid and also "fills in" around the

wheel quite well. The cotton is larger

and coarser. Preferred for grip or

"handiness", the cotton also takes

shellac very well.

The Nylon will resist weather better but

both MUST be lacquered or varnished

once received.

Your particular location will determine

final applications and type of

lacquer/varinsh to be used.

A completed 15.5" "destroyer" type wheel with Spanish (3-strand)

coxcombing on rim, (especially positioned to account for the spoke

offsets) and split six-pass turksheads at the spokes.

1' dia rim and all in S/Steel (probably by ABI or SCHMITT) takes 3/4"

tapered smooth keyway shaft.

The "split" turkshead will be a feature on all my wheels unless

something else is requested.

coxcombing on rim, (especially positioned to account for the spoke

offsets) and split six-pass turksheads at the spokes.

1' dia rim and all in S/Steel (probably by ABI or SCHMITT) takes 3/4"

tapered smooth keyway shaft.

The "split" turkshead will be a feature on all my wheels unless

something else is requested.

| FOR SALE $550.00 incl shipping |

Here's an eight-bight split turkshead. This took FOREVER to figure

out (as opposed to the six-bight split which only took a few weeks)

and makes a very pretty cover knot, but it takes about two hours to

make and tighten.... Not practical unless you really want the "WOW!"

factor on your wheel, big time! (White lead inserted just to give

some contrast for the foto: I much prefer my turksheads to be all

one colour.)

out (as opposed to the six-bight split which only took a few weeks)

and makes a very pretty cover knot, but it takes about two hours to

make and tighten.... Not practical unless you really want the "WOW!"

factor on your wheel, big time! (White lead inserted just to give

some contrast for the foto: I much prefer my turksheads to be all

one colour.)

As time goes on, I shall be posting many more fotos (hopefully I'll get the clarity angle fixed!) of

wheels and flemishes for your consideration. Thank you for looking in at the page(s) and I

hope you'll consider my services when deciding on fancy work for your craft.

I also do handrails, belts, bags and other fancywork suitable for mariners.

Vince Brennan

267-254-8984

EMAIL

wheels and flemishes for your consideration. Thank you for looking in at the page(s) and I

hope you'll consider my services when deciding on fancy work for your craft.

I also do handrails, belts, bags and other fancywork suitable for mariners.

Vince Brennan

267-254-8984

| BACK to main page |

Here's the "Half-Moku" on a tiller arm done in #30

cotton line with two 7-strand turksheads as ends.

This is "as shipped" to customer, a painting

contractor, who will varnish it on-site.

cotton line with two 7-strand turksheads as ends.

This is "as shipped" to customer, a painting

contractor, who will varnish it on-site.

| All content these pages ©2004-2018 Frayed Knot Arts. All rights reserved. Reproduction or use prohibited without prior written permission. |